The Hidden Tax of Quality System Fragmentation (and 3 Ways to Reclaim Efficiency)

This blog explores the hidden tax of quality system fragmentation—how disconnected tools and workflows silently erode margins through delays, inefficiencies, and compliance risks—and presents three powerful paradigm shifts that help manufacturers reclaim efficiency and transform quality into a strategic advantage.

From CAPA to Training — A Unified Quality Story

Learn how Unifize connects every step of the quality process—from CAPA to training—in a single, traceable thread. This blog shows how linking actions, documents, and teams in real time turns fragmented quality workflows into seamless, audit-ready outcomes.

The Role of Data & Analytics in Quality – and How Unifize Enables It

Discover how unified data and real-time analytics transform quality from reactive firefighting into proactive improvement - reducing waste, accelerating decisions, and strengthening compliance. See real results and learn the questions that separate true QMS analytics from “checkbox” dashboards.

Collaboration: The Missing Ingredient in Your Quality Management System

Your QMS logs data, not dialogue. See how chat-native records turn questions, context, and e-signatures into evidence—cutting latency, killing silos, and making quality a competitive edge.

Fixing Broken workflows for FDA and ISO-complaint companies

FDA & ISO-compliant companies excel in material flows, but broken information flows keep teams siloed, making Lean impossible. Discover how to fix them.

How Van's Kitchen Increased Visibility and Reduced Quality Process Cycle Times by 73% in 30 Days

Learn how Van’s Kitchen streamlined their quality management system and cut cycle times for audits, tests, and deviations.

Will-Burt's game changing boost to quality process cycle times

Learn how The Will-Burt Company adopted a new quality management system in under a day, streamlining audits, complaints, non-conformances, and corrective actions across 8 teams.

LaundryTec Doubles Service, Drops 3 Systems with Unifize Field Service

In under an hour, 10 LaundryTec engineers went live on Unifize—gaining visibility and cutting waste across sales, field service, work orders, scheduling, and preventive maintenance.

Biovation Labs' successful shift from MasterControl to Unifize

Learn how and why Biovation Labs, an FDA regulated nutraceutical manufacturer based in Salt Lake City, took the decision to transition from MasterControl to Unifize for their product lifecycle (PLM) and quality management (QMS) processes.

Why is selling customized products so hard? And what to do about it

Learn how managers of sales teams at companies that manufacture customized products can enable remote work and increase accountability, improve visibility and boost overall efficiency by reducing unnecessary internal emails & meetings by up to 90%.

How to reduce product design & engineering cycle times by up to 75% in 30 days

Learn how managers of product design or engineering teams at manufacturing companies can reduce cycle times by up to 75% in less than 30 days by implementing closed-loop, objective-driven conversations.

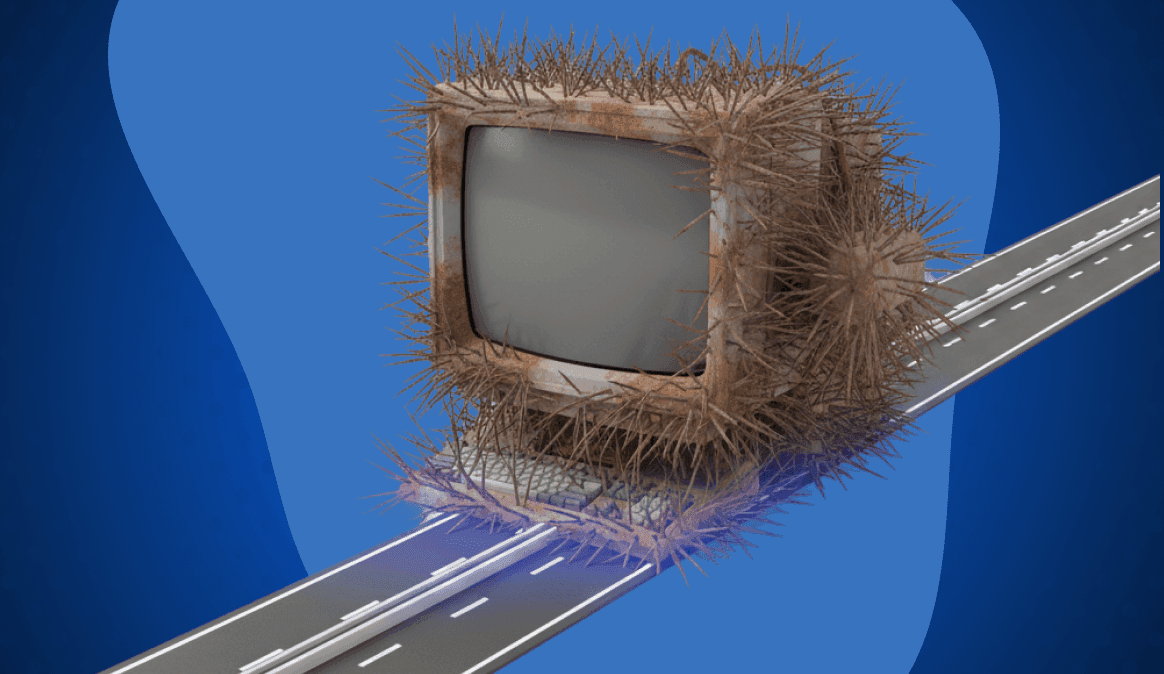

Your quality system is a “cactus” 🌵 - and 4 other reasons why a whopping 78% of your NCs / defects / complaints don’t get reported!

A study of 47 manufacturing plants found that 78% of quality events go unreported, hindering process improvement. Issues arise from digital system complexities, shop floor accessibility, misaligned goals, silos, and auditor pressures. Solutions include creating a second issue class, simplifying systems, promoting engagement, and aligning with auditors.

The Future of Quality Management Systems: Ding Dong, the database is dead!

Whether you're keen on future-proofing your quality management, exploring Lean & Six Sigma, or seeking process efficiency, this read is tailored for you. Trace the history of eQMS, uncover its enduring issues, and understand why traditional systems struggle with collaborative processes. Recognize signs of accountability, visibility, and efficiency challenges, and explore potential solutions, including integrating enterprise chat tools or embracing Collaborative Process Platforms for improved collaboration, accountability, and efficiency.

For quality & operations leaders at manufacturing companies: How to implement software in less than a day AND save up to $185,000

For quality & operations leaders at manufacturing companies: How to implement software in less than a day AND save up to $185,000 in consulting fees, expensive customization, pointless training, financial risk, administrative overheads, and IT expenses (along with pain and suffering…)

Steering Clear of SharePoint: Why It's Not Your Best Bet as an Automotive QMS

In the competitive realm of automotive manufacturing, discover the pitfalls of relying on Microsoft SharePoint for Quality Management System (QMS). Unifize emerges as the dedicated solution, addressing customization challenges, ensuring seamless integration, and offering advanced features for compliance and supplier collaboration, outperforming SharePoint in automotive quality management.

Understanding wasted time in quality processes (or why it took so long to complete that CAPA)

Before starting a software company, I used to run my own manufacturing plant making industrial enclosures for the power sector. My co-founder, Lakshman, ran a food processing unit making extruded snack pellets (🤷🏻♂️no idea what that means). We both faced the same problem – it used to take forever to get anything done. Especially in continuous improvement processes like CAPAs. If you study the process, you’ll understand why it’s so hard to get anything done.

Understanding CFR Part 11: Key Considerations for Medical Device Companies Choosing an EQMS Software

Deciphering CFR Part 11 for medical device companies seeking Quality Management System (EQMS). Vital considerations include software validation, audit trails, electronic signatures, record protection, and seamless integration. Unifize stands as a CFR Part 11-compliant solution, addressing each facet for enhanced credibility and regulatory adherence.